“Precipitated calcium carbonate – different crystalline forms which yield to predetermined physical properties”

Special controls and a mastery of the parameters involved in the precipitation reaction and later treatments are required in order to produce precipitated calcium carbonates.

When comparing to standard ground calcium carbonates (GCC), precipitated calcium carbonates (PCC) can be distinguished for:

• the possibility to achieve smaller and more uniform particle sizes

• more stable and narrower granulometric distribution

• lower abrasivity

• higher specific surface

• highest chemical purity

• defined rheological properties

Dependent on the final application we offer two different products:

CALPREC PA

Characteristics

• precipitated calcium carbonate

• scalenohedral morphology

• particular structure

• purity

Applications

• paints

• paper

• pharma and food

• plastics

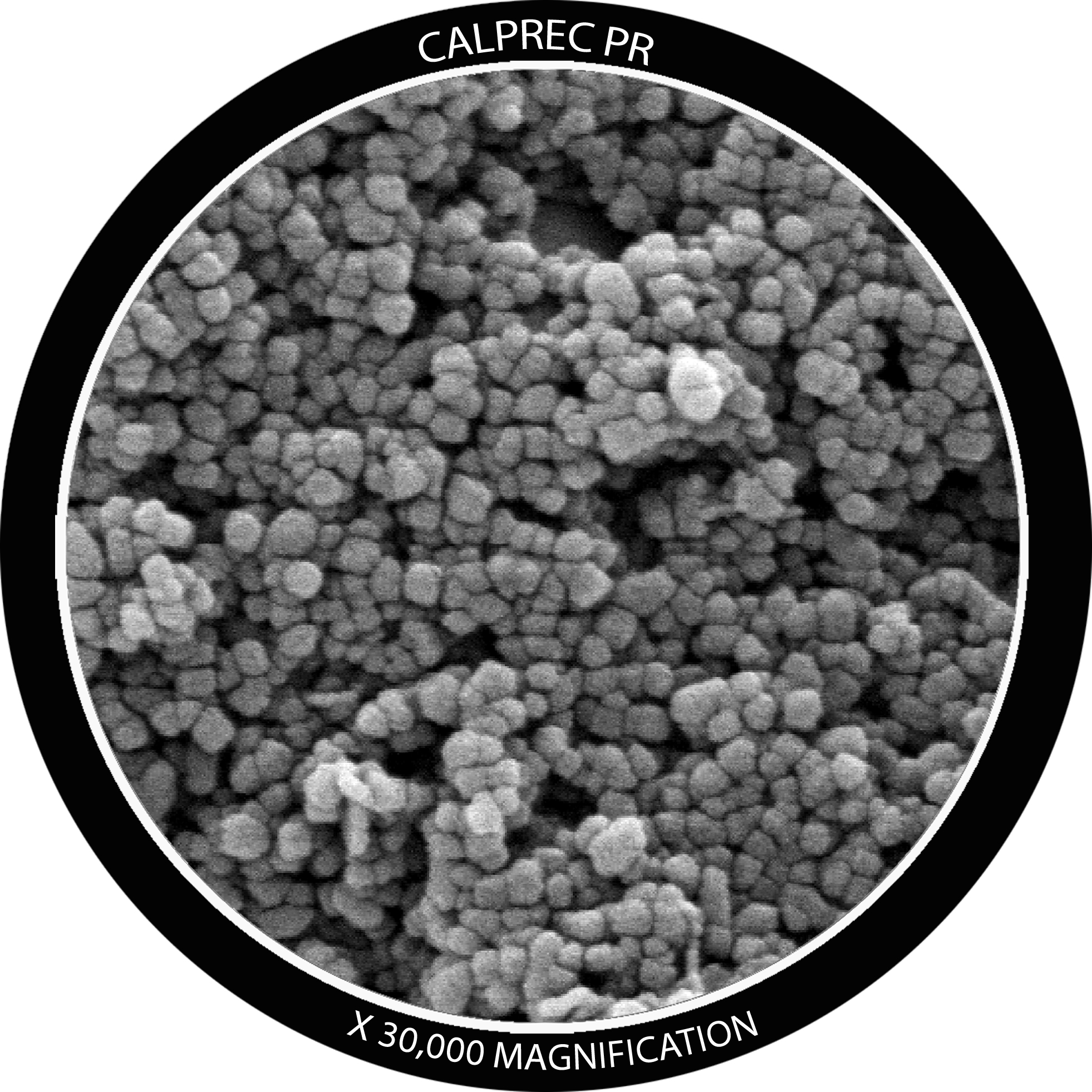

CALPREC PR

Characteristics

• coated ultrafine precipitated calcium carbonates

Applications

• adhesives

• sealants

• plastics

• inks